American Journal of Orthodontics and Dentofacial Orthopedics

Volume 4, Issue 3, p165-173, June 2024

Gianluigi Fiorillo ∙ Lorenzo Garrisi ∙ Alice Mandelli ∙ Fabio Arnò ∙ Gualtiero Mandelli ∙ Giorgio Gastaldi

ABSTRACT

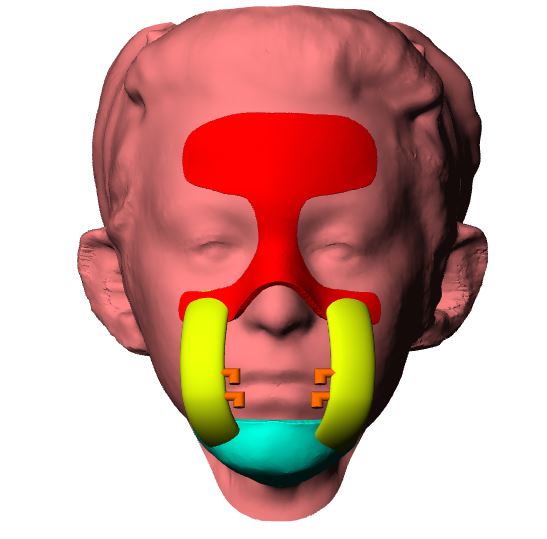

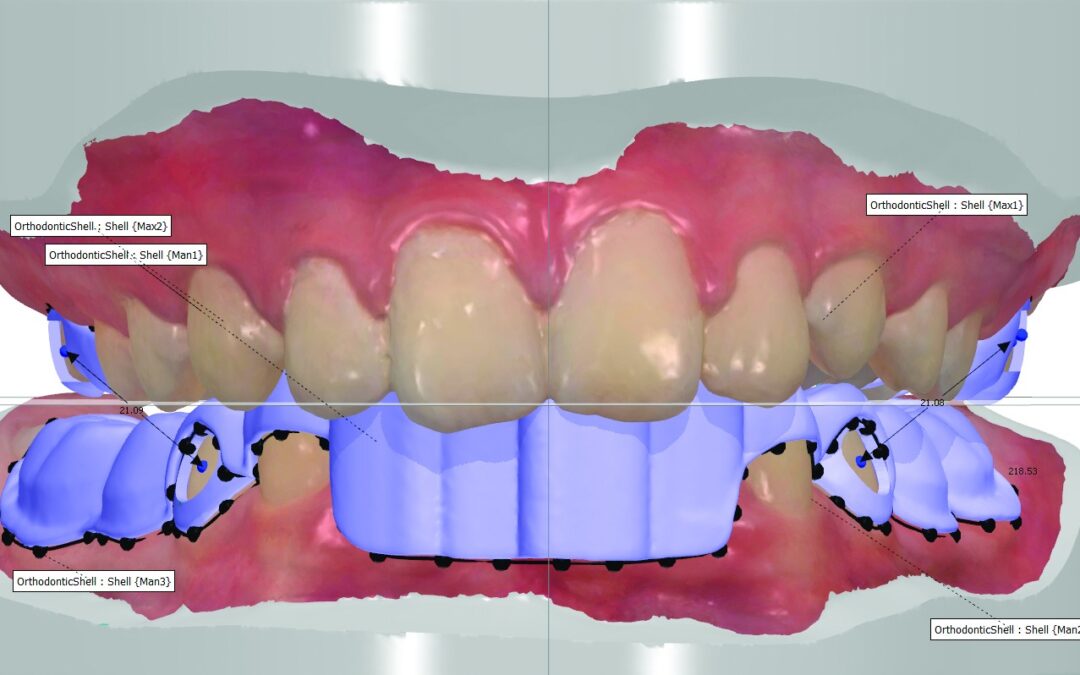

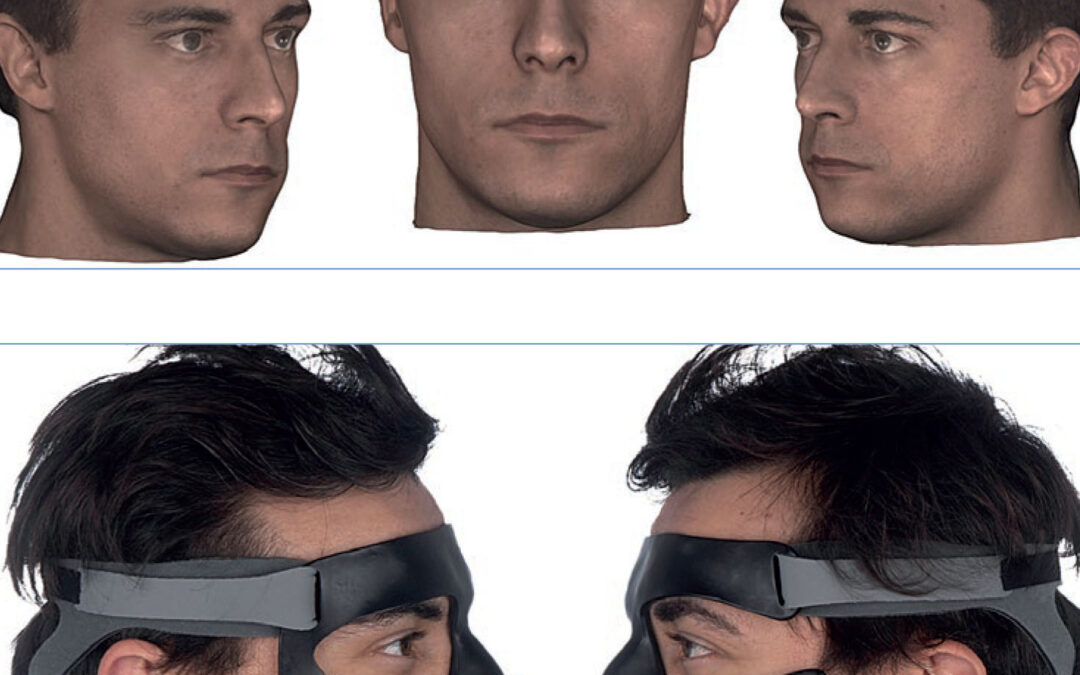

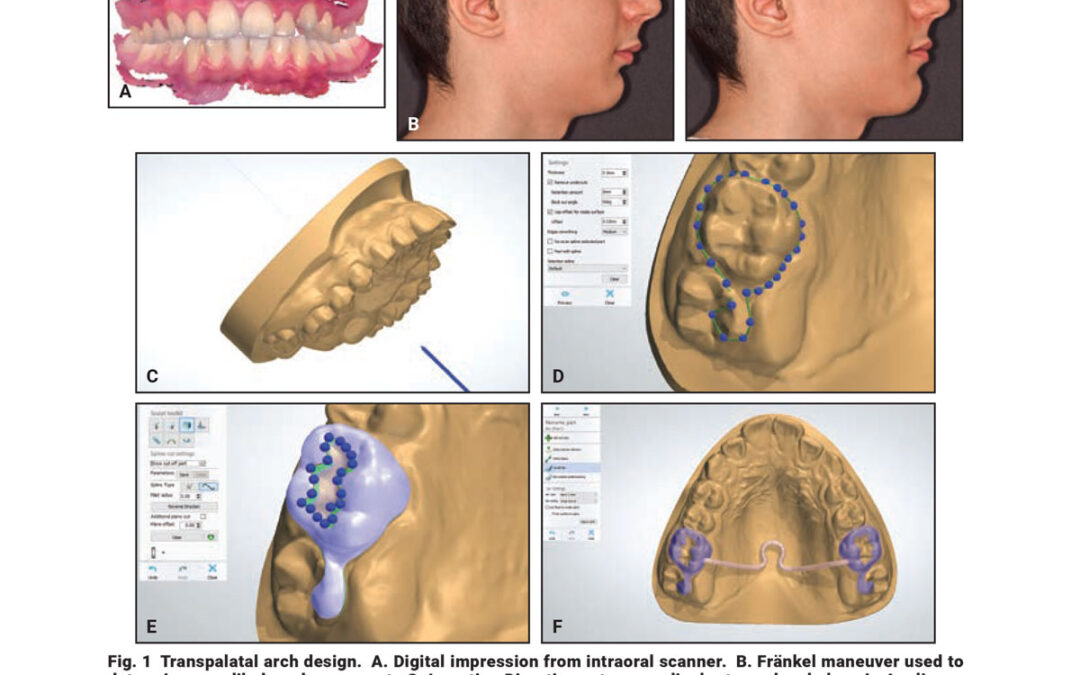

This study aimed to describe the fully digital workflow for the production design and manufacturing of a fully digital protraction facemask, a custom-made facemask designed to improve the effectiveness of orthopedic treatment in growing patients with skeletal Class III malocclusion. The first step involves generating the patient’s face model on the basis of data acquired using a 3-dimensional scanning camera. Second, a shell mask is virtually drawn and finished to guarantee 22 support zones on the forehead, cheekbones, and chin. Then, the mask is prototyped by stereolithography using biocompatible resins. The inner surface is lined with a certified, soft, antibacterial, washable material, whereas the outer surface can be customized with hydrographic printing. This paper presents a case report of an 8-year-old girl with a Class III skeletal pattern. We showed that this workflow allows similar therapeutic effectiveness as protraction while minimizing the adverse effects caused by conventional facemasks. The main advantages are as follows: matching a facial scan with a lateral cephalometric radiograph allows one to precisely define the point of application and the direction of the protraction force to reduce anterior maxillary rotation; the facial anchorage can be adjusted to increase the support surface at the frontal-zygomatic level and to extend the submental surface; the perfect fit to soft tissues and the use of specific resins tested for prolonged contact with the epidermis ensure greater comfort for the patient, reducing the occurrence of dermatitis and other skin reactions; and finally, the customized shape based on facial morphology allows patients to sleep in supine, prone, and side positions.

0 commenti